Description

XF192 Transfer Pump

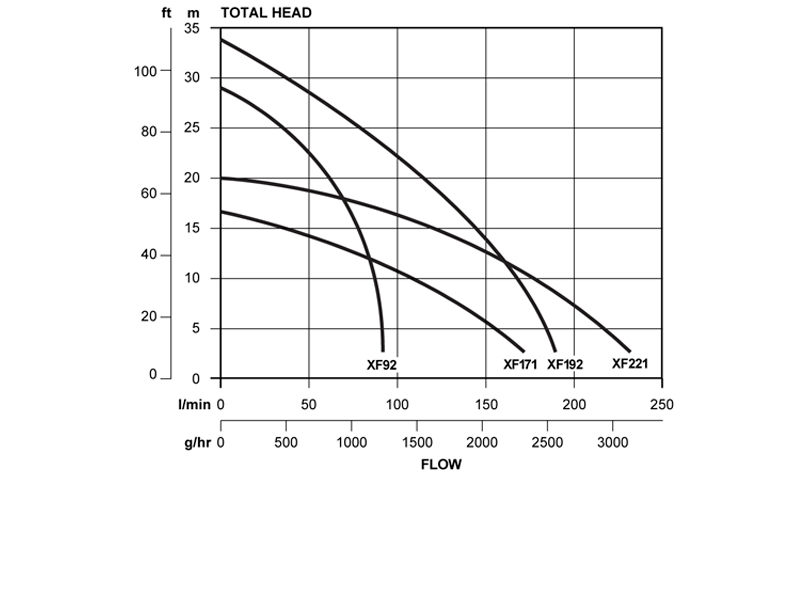

Robust and compact, 1 or 2 stage centrifugal pumps with corrosion resistant components and driven by a TEFC motor. Designed for total head duties to 33 m and flows to 225 lpm.

The XF Range of transfer pumps are ideal for pumping clean non-volatile liquids without fibres or solids in such applications as:

- Irrigation

- Aquaculture

- Water transfer

- Washing systems

- Hydroponics

MADE IN AUSTRALIA

Closed vane impellers with full length ‘D’ drive for positive robust impeller drive. Motor and pump are designed for frequent starts providing a long and reliable working life. Pump shaft and casing (on twin impeller models) are manufactured from quality corrosion resistant stainless steel. Every pump is performance and pressure tested in our factory to ensure quality and reliability.

Davey manufactured TEFC IP55 motor is corrosion resistant and resists low pressure jets of water, dust and dirt for long service life in arduous conditions.

Closed vane corrosion proof impellers with full length “D” drive for positive, robust impeller drive. Motor and pump are designed for frequent starts providing a long and reliable working life. Pump shafts (and casing on two stage models) are manufactured from quality corrosion resistant stainless steel for long service life when pumping less than perfect water. Every pump is performance and pressure tested in our factory to ensure quality and reliability.

All models come fitted with

- 2m power lead with 10 amp Australian three pin plug for ease of connection to power supply.

- High quality mechanical shaft seal for long life and reliability.

Features and Benefits

- Easy to service design for shorter downtime if or when service is required.

- Permanently split capacitor design motor for reliable starting even in low voltage circumstances.

- Double contact C3-HTG sealed bearings for quieter running and longer life.

- In-built automatic-reset thermal overload protection embedded in the motor for quick response to motor overloading. Motor overloading can be the result of extreme ambient temperature, high or low voltage (beyond specification), pump blockage and or pumping fluids heavier than fresh water (eg sea water).

- Plastic feet used on motor shell for long life in poorly drained installations.